WHAT IS ReBLOCK?

ReBLOCK is a game-changer in the construction industry. This innovative system offers modular construction solutions that are not only efficient but also offers a minimal climate impact. With ReBLOCK, we’ve reimagined the way we build, putting sustainability at the forefront.

Our modular elements are designed for rapid assembly, reducing construction time and minimizing waste. But ReBLOCK is more than just efficient; it has a minimal environmental impact. We predominantly use renewable materials and practices to leave a smaller environmental footprint.

Choose ReBLOCK for your next project, and you’re not just building; you’re building a better and greener future.

It’s construction that redefines method and mind.

Circular design

Binds C0²

Fast build pace

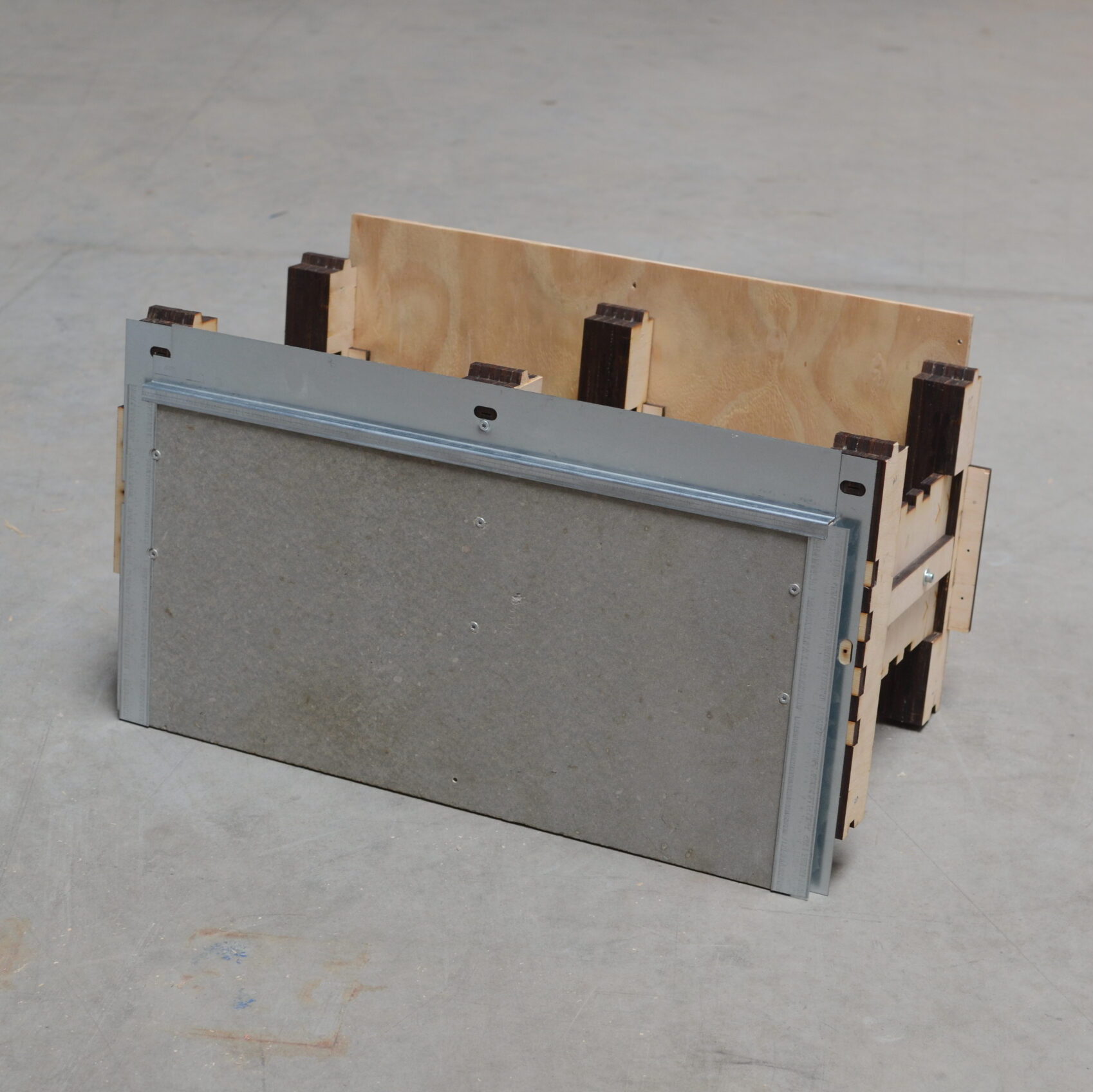

SUPER COMPACT DELIVERY

The ReBLOCK system is flat-packable to the extreme. On a single EUR-pallet we are able to flat-pack and store up to 22,7 square meters of ReBLOCK wall surface. Yep, 22,7 square meter wall surface on a single EUR-pallet. Its unlike any other modular building system out there. Due to its flat-pack capability. We greatly reduces the amount of logistics required to deliver building components for a buildingsite. Thus reducing both cost and emissions related to the delivery. Here you see two EUR pallets with a total of 45.4 square meters of ReBLOCK wall surface.

EPD VERIFIED SOLUTION

An EPD is also known as an Environmental Product Declaration. An EPD documents the environmental properties of a construction product and is developed according to recognized European and international standards. Our EPD contains the following phases A1-A5, C1-C4 & D

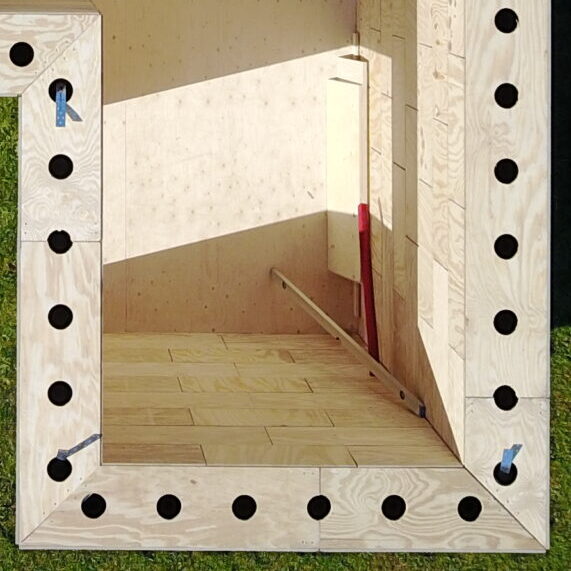

3 WORKFLOWS IN 1 GO

Build smart, build ReBLOCK.

Using the ReBLOCK system saves you time. Its innovative configuration gathers 3 workflows into 1. Every time a ReBLOCK is installed, it provides the structure of which it is planned for, the Load-bearing capacity, Wind-blocking layer and the Stabalizing shearfunction.

We concider the ReBLOCK system as the obvious Plug’N Play solution for the time conscious craftsman, who wants to work smarter, not harder.

The only tools required during construction are simple hand tools. It doesn’t get much simpler than that.

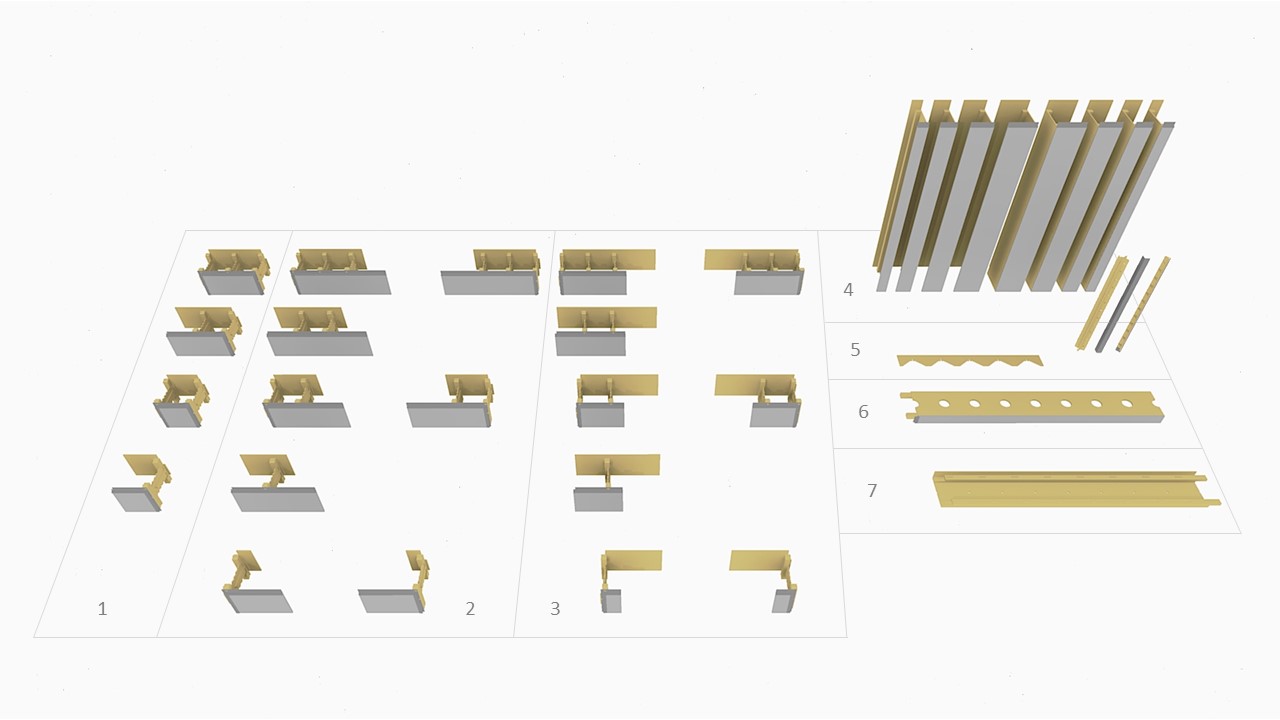

Components of the ReBLOCK system. Mix and match them as you wish to create your project block by block.

- Plain wall components.

- Outward corner components.

- Inward corner components.

- Door and Window lining components.

- Lintel and Corner reinforcements.

- Top wall plate component – with prefabricated holes for easy injection of loose fill insulation.

- Bottom wall plate component.

COMMITTED TO TRANSPARENCY

Our ReBLOCK system is made up of very few and well-known raw materials.

Plywood – It gives it immeasurably great strength and stiffness.

Cement-bonded chipboard – Provides unrivaled protection against fire, wind and the weather.

Galvanized steel profiles – Ensure an overlapping and completely tight joint between each building component.

AWARD WINNING SOLUTION

The ReBLOCK system has earned the prestigious “Solar Impulse Efficient Solution” Label. This recognition comes after a rigorous evaluation conducted by independent experts, adhering to verified standards. ReBLOCK proudly joins the #1000solutions challenge—an endeavor by the Solar Impulse Foundation. This initiative identifies solutions that excel in both profitability and sustainability.

INSULATING THE ReBLOCK

Insulating the ReBLOCKs is quite simple.

Simply use the pre-made holes at the top wall plate to inject the insulation material into the cavity of the ReBLOCK wall.

We recommend using a skilled contractor for this job, to ensure that sufficient insulation material is inject and compacted according to the insulation manufacturer’s guidelines.

A skilled contractor will typically use specialized machinery that unravels bales of compacted insulation material, and turns it into a fluffy loose fill material.

When turned into a loose fill material. The contractor uses injection hoses from the specialized machinery to guide the loose fill material up and into the pre-made holes at the top wall plate.

ITS ALL IN THE DETAILS

Delve into the intricate engineering and unveil the technical mastery of ReBLOCK. Explore the inner workings, sustainable materials, modular design, and innovative solutions that makes the ReBLOCK a groundbreaking construction system. Get ready for a deep dive into the technical world of ReBLOCK.

WEIGHT AND SIZE

ReBLOCK weight: ~7 kg.

Dimensions of the ReBLOCK

W : 600 mm

H : 300 mm

D : 341 mm

CO2 FOOTPRINT

-6,2kg CO2 e m² (A1-A3)

EFFICIENCY IN REBLOCK

One EUR pallet holds 22.7 sqm of ReBLOCK wall system.

One individual can obtain a average work rate of 12 sqm of load-bearing, wind-blocking, and stabilizing ReBLOCK wall surface per man hour.

FIRE TECHNICAL PROPERTIES

The ReBLOCK holds a REI 60 and K110-classification.

THERMAL EFFICIENCY

ReBLOCK’s minimal thermal conductivity not only minimizes energy loss but also leads to significant savings in operating costs.